Have you ever wondered what ppmvd (ref. 3% O2) means? This term is often seen in air permits and is referenced as the emission unit for pollutants such as NOx from boilers.

PPMVD stands for “parts per million by volume, dry”. For example, “9 ppmvd” refers to (9 / 1,000,000) x 100 = 0.0009% of the volume of flue gas. The reason they stipulate “dry” is because when the emission is measured, the instrument typically removes all moisture (water) from the sample. The “ref. 3% O2” is required as a benchmark for the oxygen content in the flue gas. This is because the boiler will operate at various O2 levels, and the air district needs to normalize the measurements.

Sometimes, emission limits are referenced with different O2 levels for equipment in the same plant. For example, on a boiler application, NOx may be listed as 9 ppmvd (ref. 3% O2) whereas for a gas turbine it might be 9 ppmvd (ref. 15% O2). What does it mean when the O2 levels are different?

The difference in the example above is that O2 is referenced at 3% and 15%. Looking at actual numbers will help explain the difference. Let's say a boiler or gas turbine is firing natural gas and the heat input is 100 million Btu/hr. The fuel flow is the same for each case, about 4500 lb/hr. The air flow, however, will be different.

For boilers, the burner typically runs at about 15% excess air (this is 15% extra air flow above the stoichiometric requirement). In other words, 15% of the air flow passes through the system without being oxidized. This is why the stack O2 (O2 is the extra oxygen in the boiler flue gas flow) is about 3% on a dry basis. This also explains why the 3% O2 benchmark is typically used.Based on the 100 million Btu/hr input and 15% excess air, the boiler air flow is about 81,000 lb/hr.

On the other hand, gas turbines typically run at higher excess air levels as compared to boilers. To get 15% O2, dry in the stack, the excess air works out to about 230%. The air flow would be about 233,000 lb/hr with the gas turbine application. Stack flow, or the sum of fuel and air, differs in boilers vs. gas turbines:

Boiler stack flow: 4500 + 81,000 = 85,500 lb/hr

Turbine stack flow: 4500 + 240,000 = 244,500 lb/hr

You can see that for the same heat input of 100 million Btu/hr, the stack flow will be quite different for these two applications. This also explains why the O2 benchmark is different for these two cases. When comparing the NOx values in lb/mmbtu, we have:

9 ppmvd (ref. 3% O2) NOx firing natural gas is equivalent to 0.011 lb/mmbtu

9 ppmvd (ref. 15% O2) NOx firing natural gas is equivalent to 0.032 lb/mmbtu

This means that even though both 9 ppmvd volumetric numbers are the same, the numbers are actually different on a weight basis (i.e. lb/mmbtu).

Nationwide Boiler provides temporary and permanent solutions with our CataStak SCR System for boilers, gas turbines, and other demanding applications, to meet the most stringent emissions requirements. Contact us today for more infromation. 1-800-227-1966

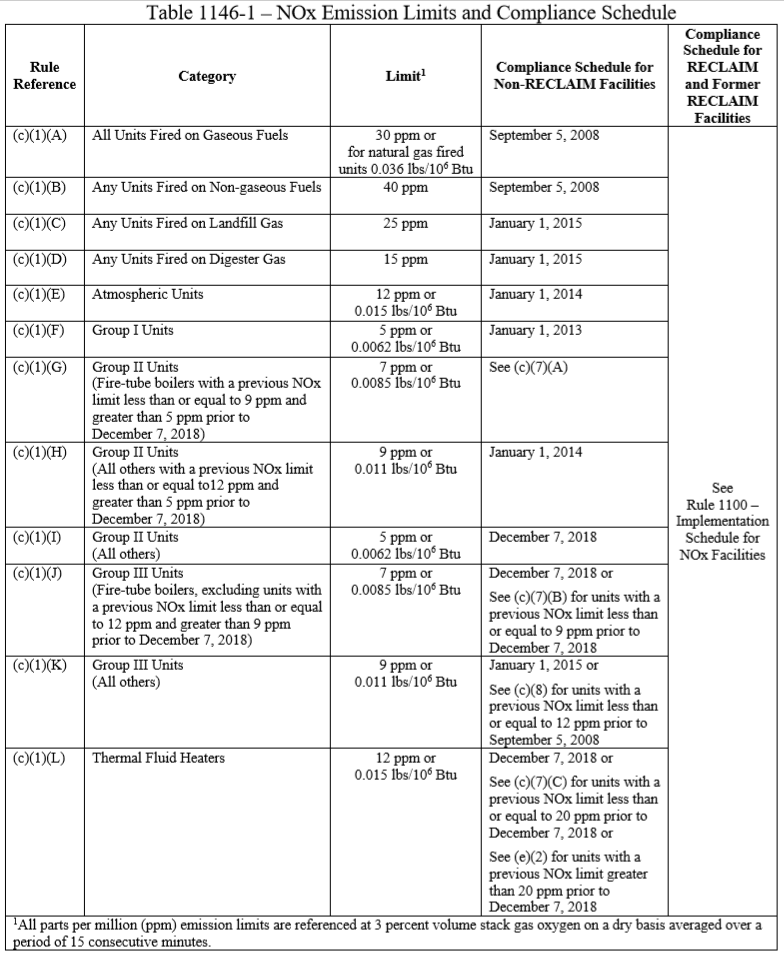

Within the RECLAIM standards, Rule 1146 outlines specific guidelines for boilers, steam generators, and process heaters that have a heat input of 5 mmBtu/hr or greater, that are utilized in all industrial, institutional, and commercial operations. This rule has changed several times, and at the end of 2018, another revision to the rule was adopted. All Group 1 units (>/= 75MMBTu/hr) as well as Group II units (20 - 75 MMBTu/hr) with an existing permit limit greater than 2 ppm must comply with a 5 ppm NOx limit. In addition, facilities that qualify must be in compliance by 2022 – 2023. The table below outlines all equipment and current limits based on category and heat input.

Within the RECLAIM standards, Rule 1146 outlines specific guidelines for boilers, steam generators, and process heaters that have a heat input of 5 mmBtu/hr or greater, that are utilized in all industrial, institutional, and commercial operations. This rule has changed several times, and at the end of 2018, another revision to the rule was adopted. All Group 1 units (>/= 75MMBTu/hr) as well as Group II units (20 - 75 MMBTu/hr) with an existing permit limit greater than 2 ppm must comply with a 5 ppm NOx limit. In addition, facilities that qualify must be in compliance by 2022 – 2023. The table below outlines all equipment and current limits based on category and heat input.