Let’s take a step back in time to a brisk day in October — a day that became a defining moment in Nationwide Boiler’s history. On October 17, 1989, at exactly 5:04 p.m. Pacific Daylight Time, a powerful 7.1 magnitude earthquake struck Northern California. For residents of the San Francisco Bay Area it was a moment frozen in time, one they would never forget.

It was a calm fall evening. More than 50,000 fans were settling into their seats at Candlestick Park for Game Three of the World Series, while millions more across the country tuned in to the live broadcast. As the stadium announcer provided pregame updates, no one could have anticipated what was about to unfold. Then, the ground began to shake. Screams erupted and the announcements stopped. ABC broadcaster Al Michaels, usually composed and articulate, was momentarily speechless. The energy of the stadium was replaced with an eerie silence. What followed was one of the most significant earthquakes in California’s history: a 7.1 magnitude event that would later be known simply as “the big one.”

In a matter of seconds, freeways collapsed, bridges broke apart, and buildings shifted from their foundations. The World Series was postponed. Fires erupted in multiple areas, including a major blaze in San Francisco’s Marina District, and millions of gallons of water were deployed by first responders to fight the flames. In the midst of widespread devastation, the city narrowly avoided a far worse outcome and utility services remained operational through the night, allowing emergency crews to respond effectively.

At Nationwide Boiler’s office in Fremont, Service Manager Neil McIntosh was still absorbing the shock of the quake. As he cleaned up broken glass and restacked books scattered across the office, he had an uneasy feeling that it would be a long night. And he was right — at 11pm that evening, the facility engineer from PG&E’s Potrero Power Plant, San Francisco’s primary power generation facility, called with a critical issue that could lead to the need for a rental boiler. And the standard question followed: “How fast can you respond?”

In the hours following the earthquake, PG&E engineers struggled to diagnose a serious problem: the plant’s electrically powered feedwater pumps, responsible for supplying water to the boilers that generated steam for turbine operation, had unexpectedly shut down. Under normal conditions, multiple backup systems would prevent any drop in water levels. But in this case, the boilers continued running without feedwater. When the pumps were eventually brought back online, it was already too late. The boilers were dangerously overheated, and it was no longer safe to reintroduce water. In a stopgap effort, a U.S. Navy ship docked next to the power plant was called in to provide emergency steam to cool the boilers. While helpful, this solution was temporary, and the city’s only other power plant was operating at full capacity to meet soaring demand. A failure at Potrero could have led to widespread outages. The only sustainable option was to deploy a high-capacity, fully equipped mobile steam plant that could deliver the right temperature, pressure, and controls to safely restart the system.

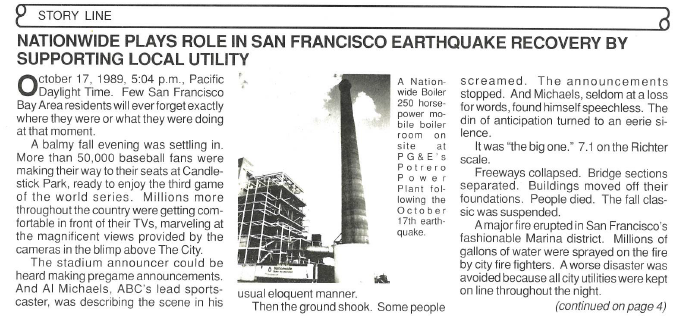

Within hours, a Nationwide Boiler 250 HP mobile boiler room was loaded and shipped to Potrero. With assistance from CalTrans and the California Highway Patrol, the unit navigated through a network of damaged freeways and arrived at the site. Shortly after arrival, the mobile boiler was brought online. The overheated boilers were cooled, the feedwater pumps were reactivated, and the turbines resumed power generation. Thanks to this rapid response, the city avoided losing a vital source of electricity at a time when it was needed most.

In the days that followed, the nation watched as rescue teams worked tirelessly to pull survivors from the rubble. The extent of the devastation was immense. But despite the tragedy, fires were brought under control, and emergency services maintained critical infrastructure under extraordinary pressure. Looking back, Neal McIntosh, a history enthusiast, often reflected on what could have happened. After the 1906 San Francisco earthquake, much of the city’s destruction was caused not by the quake itself, but by the fires that followed. Had Potrero’s boilers failed beyond recovery, the consequences in 1989 could have been similarly catastrophic.

Fortunately, Nationwide Boiler’s operations were largely unaffected, allowing our team to mobilize quickly and lend support when San Francisco needed it most. That day became more than a test of our equipment; it was a testament to the dedication of our people and the importance of being ready when every minute counts. What began as a moment of crisis became a defining chapter in Nationwide Boiler’s history — one that reminded us why readiness, reliability, and service are at the core of who we are.