There are two main boiler types that you can choose from for your specific application; watertube and firetube boilers. Deciding which of these two types will work best for you is not as easy as it may seem. It is like comparing apples to oranges; you can’t simply compare prices with steam capacity, as there are significant differences to consider.

Watertube and firetube boilers are essentially the opposite in design. In a watertube boiler, water travels through tubes which are surrounded by the by-products of combustion, or flue gas. In a firetube boiler, the flue gas travels through the tubes, which are surrounded by hot water. Firetube boilers are typically designed with either three or four sets of tubes (three- or four-pass boilers). Every set of tubes that the flue gas travels through is considered a “pass”. Boilers designed for three-passes have the stack at the rear, and boilers designed for four-passes have the stack at the front. A boiler with more passes has a higher heat extraction rate and is more efficient then one with less passes.

Watertube and firetube boilers are essentially the opposite in design. In a watertube boiler, water travels through tubes which are surrounded by the by-products of combustion, or flue gas. In a firetube boiler, the flue gas travels through the tubes, which are surrounded by hot water. Firetube boilers are typically designed with either three or four sets of tubes (three- or four-pass boilers). Every set of tubes that the flue gas travels through is considered a “pass”. Boilers designed for three-passes have the stack at the rear, and boilers designed for four-passes have the stack at the front. A boiler with more passes has a higher heat extraction rate and is more efficient then one with less passes.Watertube boilers are safer by design and generally can operate many years longer than firetube boilers. Watertube boilers are available in larger capacities and recover faster than firetube boilers. Watertube boilers can also handle higher pressures (up to 5000 psig), and have the ability to reach very high temperatures with the use of superheaters. Firetube boilers are not suitable for pressures above 350 psig and actual operating steam output of firetube boilers are less than the stated nameplate. Watertube boilers are rated at actual operating conditions.

From a maintenance standpoint, firetube boilers are typically have lower operating costs comparable to a similarly sized watertube boiler. Firetube boilers have easy access to the boiler’s firesides and tubes can easily be replaced without additional repair of the boiler. Although firetube boilers are smaller in design, they have a larger water volume than similar size watertube boilers, causing them to take longer to bring up to operating temperature from a cold start. Once a firetube boiler is started up and is operating at its desired pressure, a firetube boiler can handle a sudden upward load surge better than a watertube boiler because of the large steam disengaging area. The drawback to this feature is once the pressure of a firetube is dropped, it takes longer to catch back up. With less water volume, a watertube boiler has the ability to follow load swings more precisely and generally has better turndown than a firetube boiler.

The rule of thumb is that if you have a very constant and steady load that doesn’t change often, then a firetube boiler will work well for you. If you have a swing or varying load, then the watertube boiler is generally a better choice. With over forty-five years experience renting and selling boilers, Nationwide Boiler has the experience and knowledge you can trust to help determine which type of boiler is right for you.

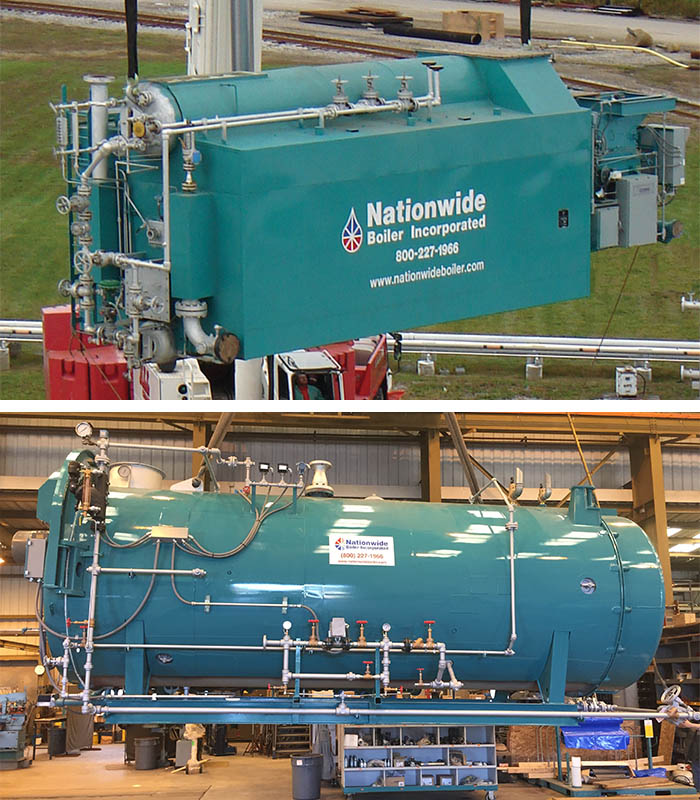

View our current inventory list that includes a wide range of new and reconditioned firetube and watertube boilers.