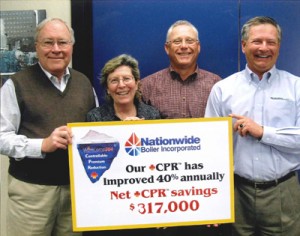

Nationwide Boiler has achieved yet another safety milestone – 2,500 days without a loss time accident! This marks the longest length of time Nationwide has gone without an accident in our forty-four years of operation. The company maintains a shop facility of 26,000 sq.ft., used for the maintenance, repair and assembly of boiler systems and auxiliaries. Nationwide Boiler’s Experience Modification Rate (EMR), a benchmark measure used for insurance premium discounts that compares worker compensation claims to other employers of similar size operating in the same type of business, has greatly improved over the last seven years. To date, Nationwide Boiler has realized a cumulative cost savings of over three-hundred-thousand dollars as a result of the company's commitments to safety.

Boiler Blog | Nationwide Boiler Inc.

Nationwide Boiler has been a proud member of the IDEA and we support the organization's goals of promoting energy efficiency and environmental quality through the advancement of district heating, district cooling and cogeneration.

On April 14, 2011 Duke burned the last of its remaining stock of coal from its famous black mountain off Coal Pile Drive. As part of Duke's Climate Action Plan to become carbon neutral by 2024, the University is converting its West Campus steam plant from a coal-burning plant to a natural gas-burning plant.

To aid in the University's efforts, Nationwide Boiler supplied a temporary 82,500 lb/hr trailer-mounted boiler for the plant, proudly delivered to the University with their Blue Devil logo. The boiler will be used until next Spring while the West Campus Steam Plant acts as a "base plant", along with steam produced at the East Campus plant, to heat Duke's buildings, sterilize surgical equipment and maintain proper humidity for art work and lab research.

Duke's director of Sustainable Duke, Tavey McDaniel Capps, said Duke's steam plant renovations make it a leader for other colleges and universities who are also focused on helping the environment. "This kind of step is pivotal in our effort to move closer to carbon neutrality," she said. "Being proactive in our sustainable efforts will make a big difference in the future."

Nationwide Boiler Inc. is excited to announce the company's new Venezuelan representative, QIS De Venezuela, C.A. QIS has been instrumental in securing a new boiler sale to a refinery customer located in Venezuela and this new agreement not only helps Nationwide Boiler gain new opportunities in Venezuela, but it also aids in Nationwide Boiler's on-going efforts to develop relationships in additional regions within South America.

Jeff Shallcross, Nationwide Boiler's CEO explains, "This new partnership is well aligned with the company's global strategic initiatives. QIS' vast experience and knowledge of the Venezuelan market strengthens Nationwide Boiler's ability to supply boiler equipment to industrial end-users searching for a reliable source of steam in Venezuela."

Nationwide Boiler Sales Engineer Tim McBride with QIS' Freddy Lindarte