To kick-off our ‘Boiler Basics 101’ series, we are starting at the very beginning. The extremely useful resource, produced by the commercial and industrial boilers that we rent, sell, service and maintain… that resource is steam.

Our business, and the boiler industry as a whole, revolves around steam. We provide boilers and related equipment for both temporary and permanent applications; equipment that works together to produce the valuable resource of steam, utilized in an abundance of processes across many different industries. So, what exactly is steam and what is it used for?

Let’s start with the chemical composition of steam. Water can exist in three physical states; solid, liquid, and vapor. These physical states, in more common terms, are referred to as ice, water, and steam. When water is heated at atmospheric pressure, its temperature rises until it reaches the highest temperature at which water can exist at this pressure. This temperature, 212F or 100C, is the saturation temperature, or boiling point. As water boils and temperature continues to increase, water particles begin to form small bubbles that rise to the surface and vaporize. This is how steam is formed.

Traditionally, steam was associated with locomotives and the Industrial Revolution. However, now steam is an integral part of modern-day technology. Not only is it an excellent source of energy and heat, but it is also sterile, which makes it ideal for use in the food, pharmaceutical, and health industries. Many other industries also utilize steam for processing, petroleum refining, utility and power, and manufacturing.

Steam has become an invaluable part of our world. Without it, many of the advances and technologies in today’s time would not be as effective or efficient as they are now.

Stay tuned for the next article in our Boiler Basics 101 series to learn about the basic anatomy of a boiler system.

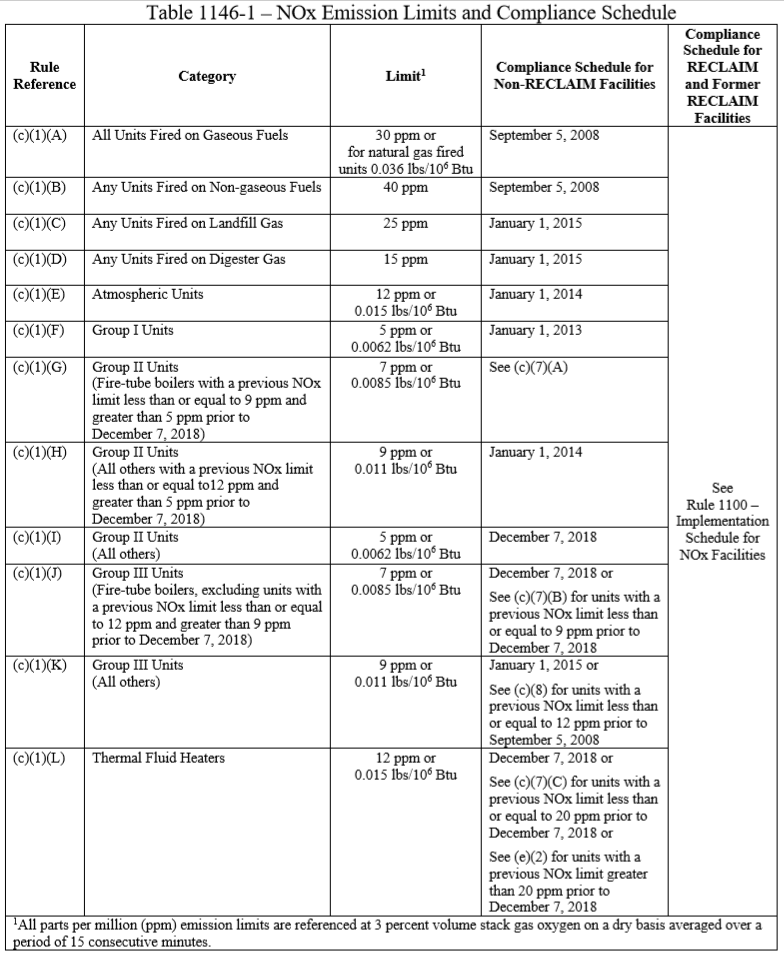

Within the RECLAIM standards, Rule 1146 outlines specific guidelines for boilers, steam generators, and process heaters that have a heat input of 5 mmBtu/hr or greater, that are utilized in all industrial, institutional, and commercial operations. This rule has changed several times, and at the end of 2018, another revision to the rule was adopted. All Group 1 units (>/= 75MMBTu/hr) as well as Group II units (20 - 75 MMBTu/hr) with an existing permit limit greater than 2 ppm must comply with a 5 ppm NOx limit. In addition, facilities that qualify must be in compliance by 2022 – 2023. The table below outlines all equipment and current limits based on category and heat input.

Within the RECLAIM standards, Rule 1146 outlines specific guidelines for boilers, steam generators, and process heaters that have a heat input of 5 mmBtu/hr or greater, that are utilized in all industrial, institutional, and commercial operations. This rule has changed several times, and at the end of 2018, another revision to the rule was adopted. All Group 1 units (>/= 75MMBTu/hr) as well as Group II units (20 - 75 MMBTu/hr) with an existing permit limit greater than 2 ppm must comply with a 5 ppm NOx limit. In addition, facilities that qualify must be in compliance by 2022 – 2023. The table below outlines all equipment and current limits based on category and heat input.