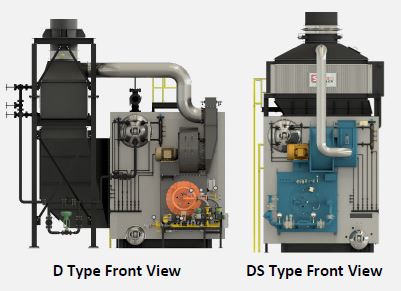

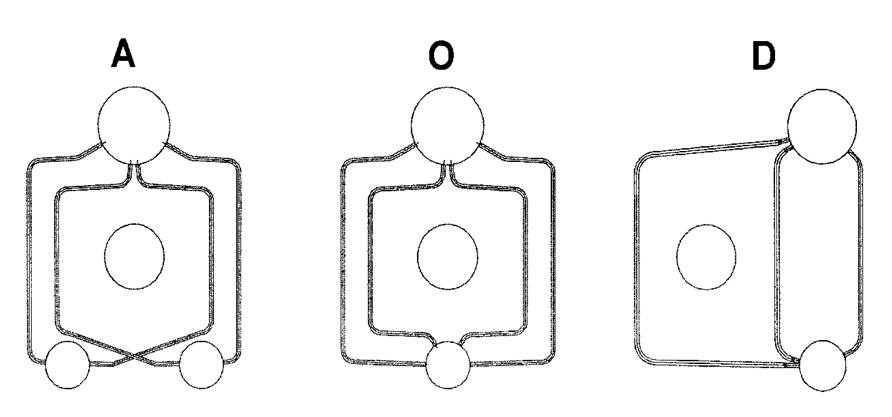

In our last blog, we reviewed the three common types of watertube boilers: D-Type, O-Type, and A-Type. There is, however, another package watertube boiler on the market today; the Ds-type, providing a fourth option to consider when you are planning for a new boiler. In fact, the Ds-type design is patented and manufactured by Superior Boiler and is one of their most popular watertube boiler models.

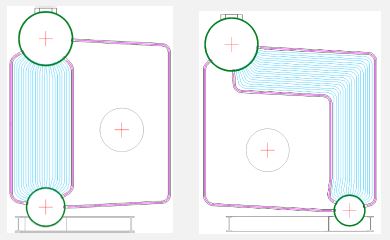

With Ds-type boilers, the furnace is more centralized and the cross section is more square compared to the rectangular furnace cross section of a D-type boiler. The square shape improves the heat flux from the burner due to walls being more equidistant from the heat source, and with a more uniform heat flux we get improved heat transfer with lower emissions.

Compared to D-type boilers, the Ds-type offers additional features and advantages:

- Improved shipping and rigging due to a more centralized center of gravity.

- More compact footprint; roughly 1-2ft shorter than typical package boiler.

- No need for a burner platform since the burner is lower to the ground.

- The option to be designed with a top exhaust outlet, providing space savings with the ability to mount the economizer in a vertical configuration above the boiler. D-type boilers are limited to a side outlet and horizontal, ground-mounted configuration.

- An overall lower capital cost caused by fewer transitions and breeching, smaller fan requirement, better heat transfer, and better performance.

The Ds-type boiler is also known as Superior’s “Shawnee” model. With design pressures of up to 1,200 psi, these boilers can be built to supply as little as 10,000 lbs/hr to as much as 250,000 lbs/hr of saturated or superheated steam. The patented design provides an unmatched, compact footprint and is a great option when looking to replace an existing unit or add capacity to your facility.

Contact us today to learn more about how Superior’s Ds-type boiler could be a good match for your next project. 800-227-1966

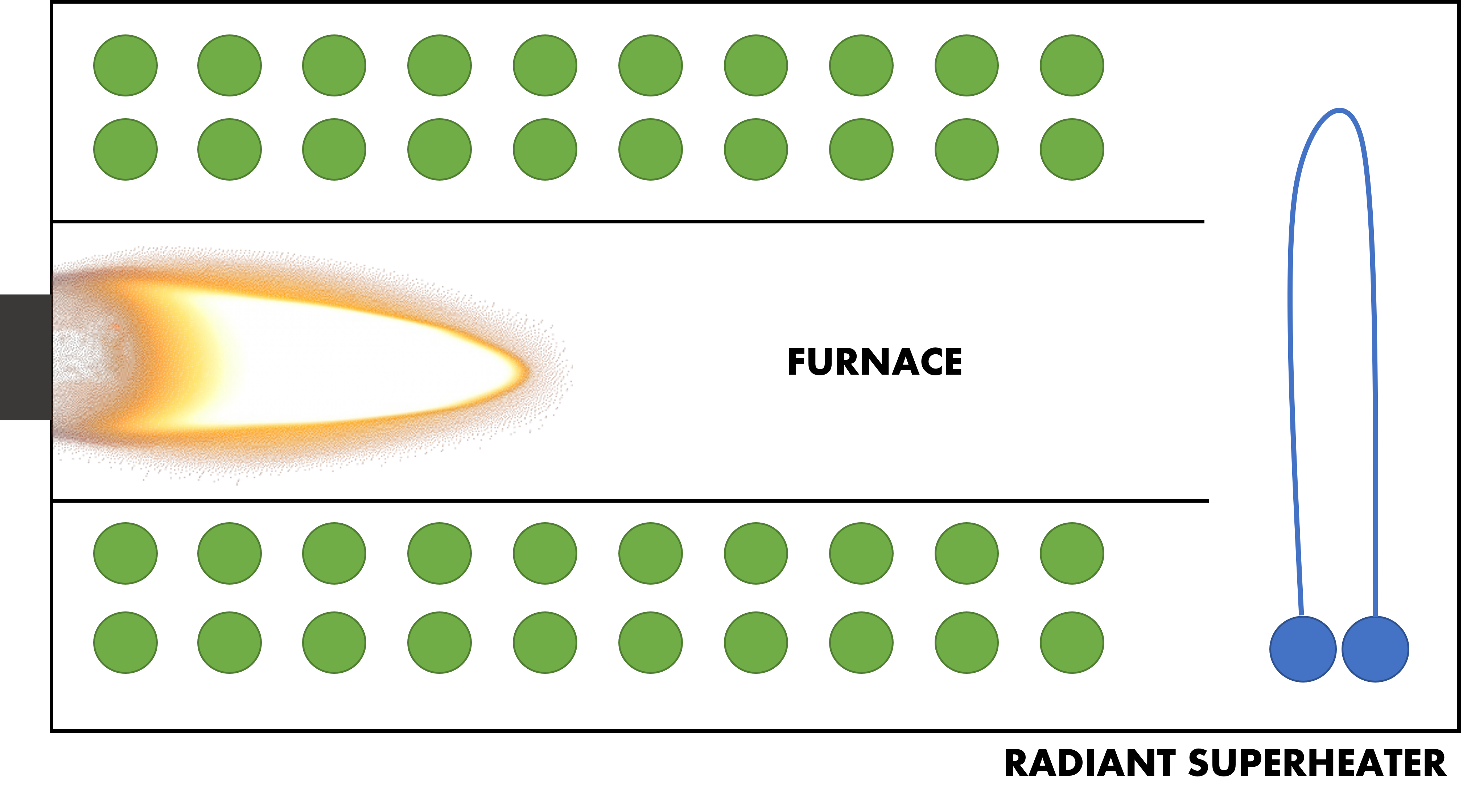

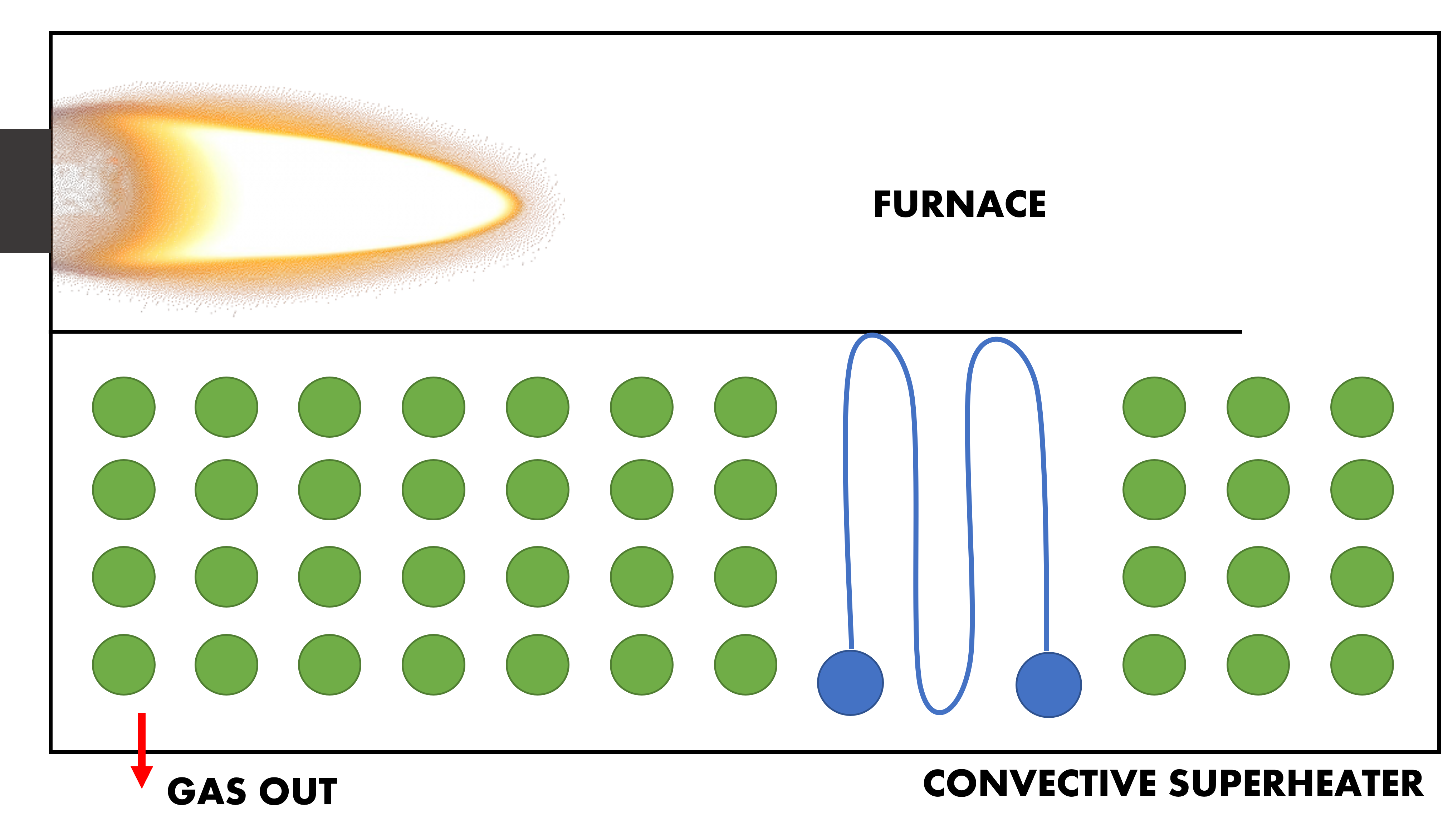

On D-Type boilers, this extra tube bank is added to the convection section (or the generating bank). This is called the convective design. The benefit of this design is the steam coils are out of the radiant heat zone of the burner (the extra heat transferred uses convection only). However, performance is not as good as radiant style superheaters which means at reduced loads, the steam temperature drops off quickly.

On D-Type boilers, this extra tube bank is added to the convection section (or the generating bank). This is called the convective design. The benefit of this design is the steam coils are out of the radiant heat zone of the burner (the extra heat transferred uses convection only). However, performance is not as good as radiant style superheaters which means at reduced loads, the steam temperature drops off quickly.